Electrical hazards are often present in many work areas and job sites. When pre-planning work or tasks, electrical hazards are often considered in the Job Safety Analysis (JSA) for electrical work or Job Hazard Analysis (JHA).

Many electrical hazards are easy to identify. These hazards include:

- Contact with live wires resulting in electric shock and burns

- Interaction with overhead power lines, commonly when workers are using heavy construction equipment that extends vertically and not having a spotter when working around overhead power lines

- Exposed electrical wires and electrical parts on tools and equipment

- Overloaded circuits, especially in conjunction with inadequate wiring

- Improper grounding, sometimes caused by workers deliberately removing the ground pin on an electric plug to fit a two-prong extension cord

- Damaged wire insulation, causing electrical conductors to make contact with each other, tools, or a worker's body

- Working in wet conditions using electrical tools and equipment

- Fires due to faulty and / or inadequate wiring

- Ignition of fires or explosions due to electrical contact with potentially flammable or explosive materials, including improper storage of these types of materials and when working with these materials

- Arc flash and arc blast when working on energized electrical equipment

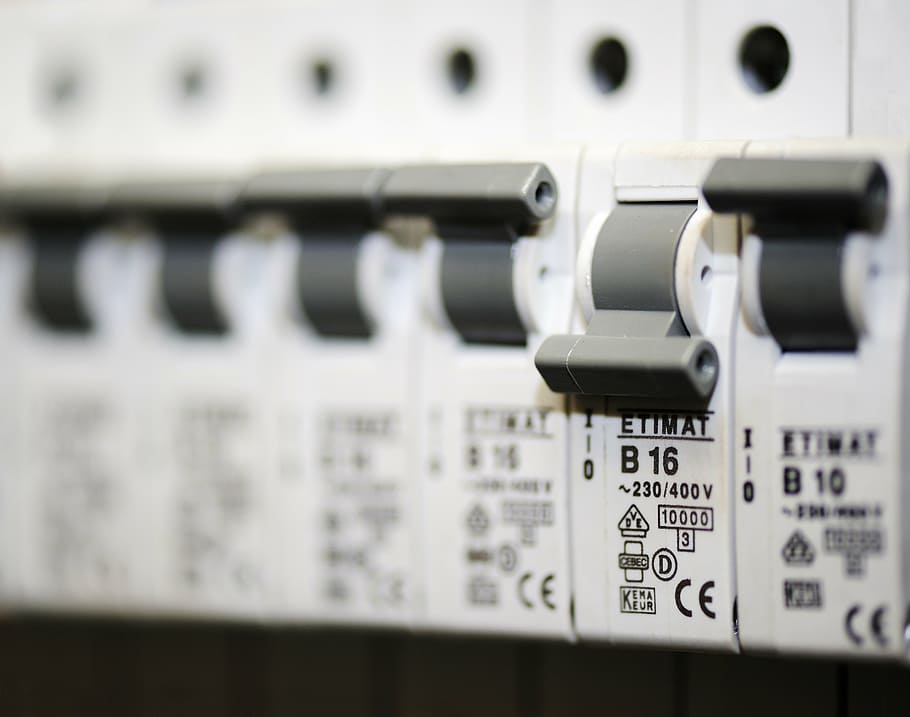

When discussing electrical safety and how to mitigate the hazards associated when working with electrical circuits during your Job Safety Analysis, it can be helpful if everyone on the team understands the difference between a circuit breaker and a ground fault circuit interrupter (GFCI). Circuit breakers cutoff the flow of current in the circuit when the amount of current being drawn is greater than the rating of the circuit breaker. The reason the current in the circuit may be higher than what the circuit is designed to carry could be due to too much equipment attached to the circuit such that when all of the equipment is operating, they put a combined load on the circuit that exceeds the safe operating rating. A single piece of equipment, that draws more current than the amount that the circuit breaker is designed to carry, can also cause the breaker to “trip.” A short is another way to cause a current overload condition and trip the circuit breaker. A short circuit is when the hot wire and a grounded object or the natural wire in a circuit are directly connected together. A short is a common hazard when there is damage to wire insulation or internal damage to tools and equipment. Striking overhead lines with a piece of metal equipment can cause a short circuit.

Circuit breakers are designed to protect the electrical wiring and the equipment attached to the circuit. Ground fault circuit interrupters, on the other hand, are designed to protect people. The U.S. Department of Labor, Occupational Safety & Health Administration (OSHA) has detailed requirements for GFCI protection at construction sites.

Like circuit breakers, GFCI's also cutoff the flow of current, but GFCI's do not trip when the circuit load is above a given value. GFCI's trip when the amount of current flowing into the circuit is not the same as the amount of current flowing out of a circuit. Ground fault circuit interrupters are very sensitive to this difference in current on both sides of the circuit. GFCI's will typically cutoff the flow of current in a circuit if the difference between the two sides of the line are different by as little as 4 to 6 milliamps. Consider that a typical home circuit is rated for 20 amps. 4 milliamps are equal to 0.004 amps, a very small amount when compared to the rated capacity of the circuit!

Typical residential GFCI Image Credit ElectricalSlang.com

|

Typical construction site GFCI Image Credit Eaton

|

Water is a conductor of electricity and can cause a hazardous condition if some of the current flows along the path to the water. This causes an unbalanced current flow in the circuit that a GFCI would catch, but a circuit breaker would not. If the path of the current flow is through the worker's body, this could potentially be a life threating hazard.

Because water can be a good conductor of electrical current, the Job Safety Analysis or Job Hazard Analysis should include a section that evaluates the hazards associated with using electrical tools and equipment in wet environments. The evaluation needs to include type of power tools and other equipment as well as how close to the water the workers will be conducting their tasks. When the work is in wet or outdoor rainy conditions, the tools and equipment should always be connected to a circuit that includes a GFCI.

The Job Safety Analysis for electrical work or Job Hazard Analysis should include an assessment of electrical hazards for each job task, even if the workers are not directly handling electrically energized tools or working on electrically energized equipment. An example might be a dump truck operator lifting the bed of the truck to dump a load, that has not considered that the elevated bed of the truck may strike overhead power lines.

Check lists can be prepared and distributed to the workforce to assist them in identifying electrical hazards. The check list should include the most common electrical hazards and any site-specific electrical hazards for the jobsite. Conditions on jobsite are constantly changing, so updating the Job Safety Analysis hazards, and communicating the new hazards to the workers, is an on-going requirement to keep the workforce safe.

When it comes to keeping workers safe one best practice is pre-planning and utilizing a Job Safety Analysis or an Activity Hazard Analysis for electrical work. JSABuilder.com is a fast and easy on-line job safety analysis app to assist in preparing your JSA. Set up a free trial account today and follow us on Twitter @JSABuilder, where we Tweet about Health and Safety, provide Safety tips, and updates on current Health and Safety topics.