Welding is a hazardous undertaking and precautions are required to avoid burns, electric shock, vision damage, inhalation of poisonous gases and fumes, and exposure to intense ultraviolet radiation. Development and implementation of a thorough Job Safety Analysis (JSA) is one of the best ways to ensure that your employees involved in welding, as well as all employees who may be near the welding operation, are safe. Using the JSA software, JSABuilder, is a great way to develop your JSA for welding.

Welding can be conducted in a variety of ways and can create a wide variety

of potential health risks. Identifying the risks then coming up with a plan

for eliminating or controlling them is the purpose of the JSA. But to be

able to properly conduct a risk assessment and/or create a viable JSA, it

is important to understand what the potential hazards may be.

Welding can be conducted in a variety of ways and can create a wide variety

of potential health risks. Identifying the risks then coming up with a plan

for eliminating or controlling them is the purpose of the JSA. But to be

able to properly conduct a risk assessment and/or create a viable JSA, it

is important to understand what the potential hazards may be.

First off, what is "welding" and why can it be such a risky task? According to Wikipedia, welding is a fabrication process that joins materials (metals or thermoplastics), by using high heat to melt the parts together and then allowing them to cool, causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal. In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material that cools to form a joint that can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld.

Welding in its different forms, uses many different energy sources such as a gas flame (chemical), an electric arc (electrical), a laser, and electron beam, friction, and/or ultrasound. Controlling the risks associated with these different types of energy sources through development and implementation of a thorough JSA or Activity Hazard Analysis (AHA) is the best way to ensure that employees take the necessary steps to ensure that they stay safe through the welding process, and that their actions do not result in an event leading to the injury or death of another individual, or that result in property damage.

The U.S. Occupational Safety and Health Administration (OSHA) has a lot of information available regarding welding and the hazards that may be present. In their Welding Fact Sheet, OSHA classifies welding into two groups: fusion (heat alone) and pressure (heat and pressure).

There are three types of fusion welding:

-

Electric arc welding: The most widely used type of fusion welding, employs

an electric arc to melt the base and filler metals. These methods can use

either direct current (DC) or alternating current (AC), and consumable or

non-consumable electrodes. The welding region is sometimes protected by

some type of inert or semi-inert gas, known as a shielding gas, and filler

material is sometimes used as well. Arc welding types include:

- Shielded Metal Arc Welding (SMAW): also known as "stick welding;"

- Gas Metal Arc Welding (GMAW): also known as MIG (metal, inert gas);

- Gas Tungsten Arc Welding (GTAW) also known as TIG (tungsten, inert gas);

- Flux-Cored Arc Welding (FCAW); very similar to MIG;

- Submerged arc welding (SAW), usually called Sub Arc;

- Electroslag welding (ESW): similar to electro-gas welding (used for thicker materials).

- Gas or oxy-fuel welding: Uses a flame from burning a gas (usually acetylene) to melt metal at a joint to be welded, and is a common method for welding iron, steel, cast iron, and copper.

- Thermit welding: Uses a chemical reaction to produce intense heat instead of using gas fuel or electric current.

Pressure welding uses heat along with impact-type pressure to join the pieces.

According to estimates, the Centers for Disease Control and Prevention (CDC) reports that more than 400,000 men and women are employed in welding and related occupations in the U.S. Some studies suggest that occupational exposures to welding fumes may pose the risk of serious respiratory, neurological, and reproductive effects. Depending on the type of welding, base and filler materials used, rod composition, etc., welding fumes may contain a wide variety of heavy metals (e.g., aluminum, antimony, arsenic, beryllium, cadmium, chromium, iron, lead, manganese, nickel, silver, and zinc). These fumes, in combination with the gases used for the process (e.g., nitric oxide, carbon dioxide or monoxide, ozone, phosgene, and hydrogen fluoride), or shielding (e.g., argon, helium, nitrogen, and carbon dioxide) may create a highly toxic mixture for the welder and those in proximity to the welding operation.

In addition to welding fumes, welders may also be exposed to particulate

matter. Flux-cored arc welding and shielded metal arc welding produce smoke

which may contain oxide particles of varying sizes – the smaller

particles are more dangerous because they have the ability to cross the

blood-brain barrier. Carbon dioxide, ozone, and fumes containing heavy

metals such as manganese can be very dangerous. For example, even at low

levels (<0.2 mg/m3), the CDC notes that manganese may lead to

neurological problems or to damage to the lungs, liver, kidneys, or central

nervous system.

In addition to welding fumes, welders may also be exposed to particulate

matter. Flux-cored arc welding and shielded metal arc welding produce smoke

which may contain oxide particles of varying sizes – the smaller

particles are more dangerous because they have the ability to cross the

blood-brain barrier. Carbon dioxide, ozone, and fumes containing heavy

metals such as manganese can be very dangerous. For example, even at low

levels (<0.2 mg/m3), the CDC notes that manganese may lead to

neurological problems or to damage to the lungs, liver, kidneys, or central

nervous system.

Eye injuries are also a potentially significant result of a poorly designed or implemented Job Safety Analysis when welding. Exposure to excessive ultraviolet (UV) light may result in photokeratitis (or ultraviolet keratitis), a painful inflammation of the cornea and possible burning of the retinas. Also known as arc eye, welder’s flash and bake eyes, these potentially harmful effects can be mitigated with the use of proper controls such as welding helmets and goggles. Bystanders must also be protected from the UV light – PVC curtains may be employed to shield workers or individuals outside of the direct welding area.

In addition to the health risks associated with being exposed welding fumes or gases, welders must be aware of the potential for burns, fires and/or explosions. Because many welding processes use an open electric arc or flame, which is often combined with compressed gases, the risk of burns, fire and possibly explosion is significant.

So given all of the inherent risks associated with welding, how can you ensure that your workers, or you if you are the welder, are safe during the welding operation? The first step is to understand the type of welding that will be done, and the specific risks associated with that method. Once the job has been defined and the equipment chosen, then putting together the JSA or AHA will provide you with a written method to reduce the risks.

Here are some of the primary areas and questions that you need to address as you develop the JSA or AHA:

- Prior to installing the welder, you should determine if your present electrical system is adequate to handle the increased load required by the welder.

- Make sure that the welder is installed in compliance with State, OSHA and National Electric Code (NEC) requirements by a qualified electrician.

- The frame or case of the welder must be properly grounded;

- A safety-type disconnecting switch or controller shall be located near the machine;

- Ensure that the welder is protected by a properly sized fuse or circuit breaker on an independent circuit;

- Ensure trash cans are emptied or capped near the welding operation - a spark can ignite up a trash can very easily;

- Keep flammable materials in a proper flammable cabinet and discard flammable rags into proper containers;

- Establish barriers of some kind to prevent bystanders from entering the work area and use walls or shades to prevent them from direct view of the welding arc. Translucent welding curtains made of polyvinyl chloride plastic film can shield people outside the welding area from the UV light of the electric arc.

- Keep work-spaces CLEAN - welders have limited field of view and if they are using an auto-darkening hood or a ventilated hood they often walk around with the hood down and limited field of view.

- Secure all welding gasses that are contained in high pressure cylinders (2000 PSI or more) so they cannot fall, and make sure cylinders are properly labeled and capped.

- The welding area should always be equipped with a fire blanket and a well-stocked first aid kit. It is desirable that one person be trained in first aid to treat the minor injuries that may occur.

- The welder should be located in an area with adequate ventilation.

- If welding with materials that are not considered hazardous, a ventilation system that will move 2000 cubic feet per minute of air is satisfactory. However, when working with hazardous or toxic materials, a more robust ventilation system will be needed such as an exhaust system or fume extractor.

- Keep fume hoods, fume extractor guns and vacuum nozzles as close to the plume source to remove the maximum amount of fume and gases, while not interfering with the work.

- Portable or flexible exhaust systems can be positioned so that fume and gases are drawn away from the welder.

- Keep exhaust ports away from other workers.

- Consider substituting a lower fume-generating or less toxic welding type or consumable.

- Do not weld in confined spaces without ventilation. Refer to applicable OSHA regulations.

- Welding units are capable of producing temperatures in excess of 10,000 degrees F; it is very important to make sure that the area is fire safe.

- Use metal sheets or fire-resistant curtains as fire barriers.

- The flooring should be concrete or another fire-resistant material, and cracks in the floor should be filled to avoid sparks and hot metal from entering.

- Remove or protect all combustibles from ignition sources.

- Employ someone as a "fire-watch" to check for any fires that could go undetected until the welder has finished the job (equipped with proper PPE of course).

- Have appropriate fire extinguishing equipment on hand such an ABC-type dry chemical extinguisher.

- Make sure individuals are properly trained in the handling of fire extinguishers and understand the company’s emergency communication and response actions.

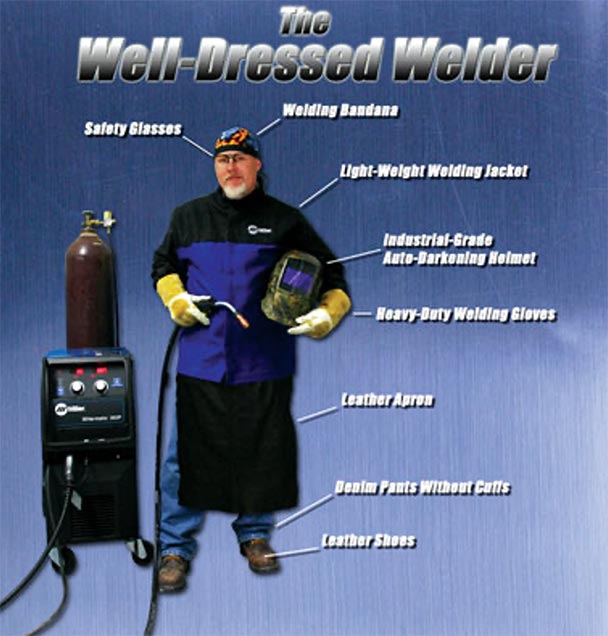

- General PPE for the welder includes an appropriately shaded welding hood, appropriately selected gloves for the welding application, safety glasses, safety boots, and ideally fire-retardant long-sleeved coveralls.

- PPE for others on site might include closed toe leather shoes, pants, long sleeves, safety glasses, and no synthetics (Nylon, polyester, Spandex, etc.) Synthetic clothing such as polyester should not be worn since it may burn, causing injury.

- Always avoid clothing with tears, snags, rips, or worn spots as these are easily ignited by sparks. The sleeves and collars should be kept buttoned.

- When welding or cutting metals with hazardous coatings such as galvanized metal the operator should use a supplied-air type respirator, or a respirator specially designed to filter the specific metal fume.

- The hands should be protected with leather gauntlet gloves.

- A pair of high-top leather shoes, preferably safety shoes, is good protection for the feet. If low shoes are worn, the ankles should be protected by fire resistant leggings.

- Eyes should be protected by transparent goggles if the person wears prescription glasses or safety glasses if not.

- A welding helmet or hand shield with filter plate and cover plate is mandatory for eye protection from the harmful rays of the arc. The filter plate should be at least shade #10 for general welding up to 200 amps. However, certain operations such as carbon-arc welding and higher current welding operations require darker shades. Never use a helmet if the filter plate or cover lens is cracked or broken.

- A flame-proof skull cap to protect the hair and head.

- Hearing protection in noisy situations is recommended.

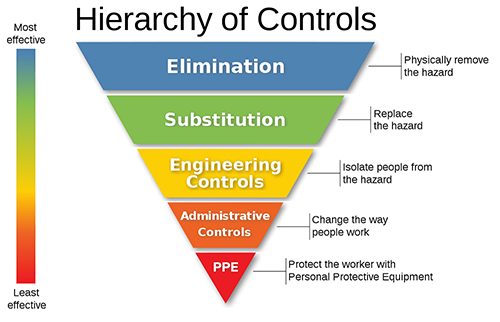

When developing your JSA, and particularly if you are using JSABuilder, you

should prioritize your controls per NIOSH’s Hierarchy of Controls:

always try to eliminate the risk or hazard first, then if that is not

possible, try to find a substitute operation (e.g., different type of

welding), then implement engineering controls to reduce the severity of the

potential hazards (e.g., better ventilation, addition of exhaust hoods),

then employ administrative controls (permit to work, hot-work permit,

restricted personnel access), and finally, make sure that you have selected

and provided the appropriate PPE for your employees, and especially any

involved in welding or other hazardous activity.

When developing your JSA, and particularly if you are using JSABuilder, you

should prioritize your controls per NIOSH’s Hierarchy of Controls:

always try to eliminate the risk or hazard first, then if that is not

possible, try to find a substitute operation (e.g., different type of

welding), then implement engineering controls to reduce the severity of the

potential hazards (e.g., better ventilation, addition of exhaust hoods),

then employ administrative controls (permit to work, hot-work permit,

restricted personnel access), and finally, make sure that you have selected

and provided the appropriate PPE for your employees, and especially any

involved in welding or other hazardous activity.

So just to sum up, there is a wide variety of potential health and safety hazards associated with welding operations. Health hazards include exposures to metal fumes and particulate- laden smoke, and exposure to ultraviolet (UV) radiation; safety hazards include burns, eye damage, electrical shock, cuts, fires/explosions, and possible injuries to extremities. Many of these hazards can be controlled with proper work practices and PPE. Knowing and understanding each type of welding to be used on your job site is very important, and developing a robust, well thought-out Job Safety Analysis or Activity Hazard Analysis is a great way to fully define the risks and come up with a viable plan to keep your workers safe, and protect your operation! Using JSABuilder is a great way to develop, then share your welding JSAs!

The following links provide additional information about potential hazards and possible solutions associated with welding operations.